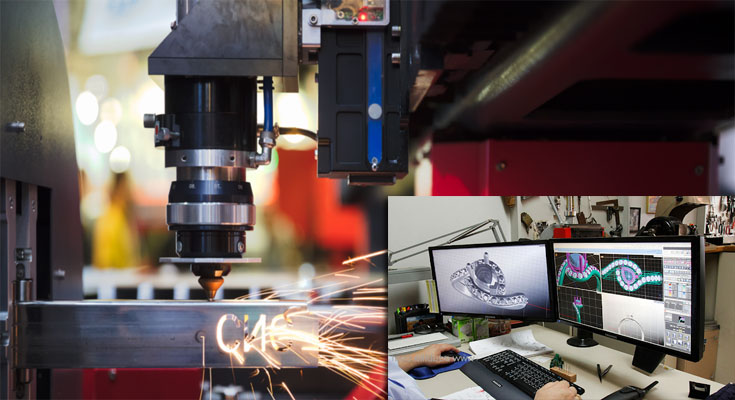

Few developments in the modern era have had more far-reaching impacts than CAD or computer-aided design. This innovative technology began to appear on the scene in the 1960s and its applications have grown throughout the following six decades. The use of CAD has helped society in the following ways:

- Increased productivity

- Improved design

- Increased quality

- Enhanced creativity

- Improved collaboration

While its use has been widespread, it is certainly influential in the area of machining. Here are some ways CAD enhances the process of manufacturing.

Better Products

High performance presses that run various inks and substrates require precision end seals. With the use of state-of-the-art CAD equipment, superior seals can be made when compared to die cut equipment. There is also an advantage in terms of cost-effectiveness and repeatability. These seals can be made from felt, foam, composite and rubber materials, and the replication process is swift. An assortment of OEM or custom seals can be made to fit the needs of the printing industry.

Greater Customization

The early days of CAD had plenty of features but a limited ability to customize processes. That has changed in recent years. Advanced CAD software often has a high level of customization. This can take a variety of forms. For example, as more CAD options exist in the cloud this opens up areas of collaboration. If one team of designers cannot fulfill a customer’s request for a personalized product, the project can be handed off to freelancers that work remotely.

Enhanced Efficiency

Engineering information can be transmitted directly to machines that are involved in the production of a certain product. This allows for a quicker switch from one product to another. The fast transfer of CAD information limits production delays in the plant, resulting in greater client satisfaction. There is also potentially less wastage of raw materials, resulting in additional savings to the production company.